The sustainability of construction projects involves considering environmental, social, and economic factors throughout the project’s life cycle.

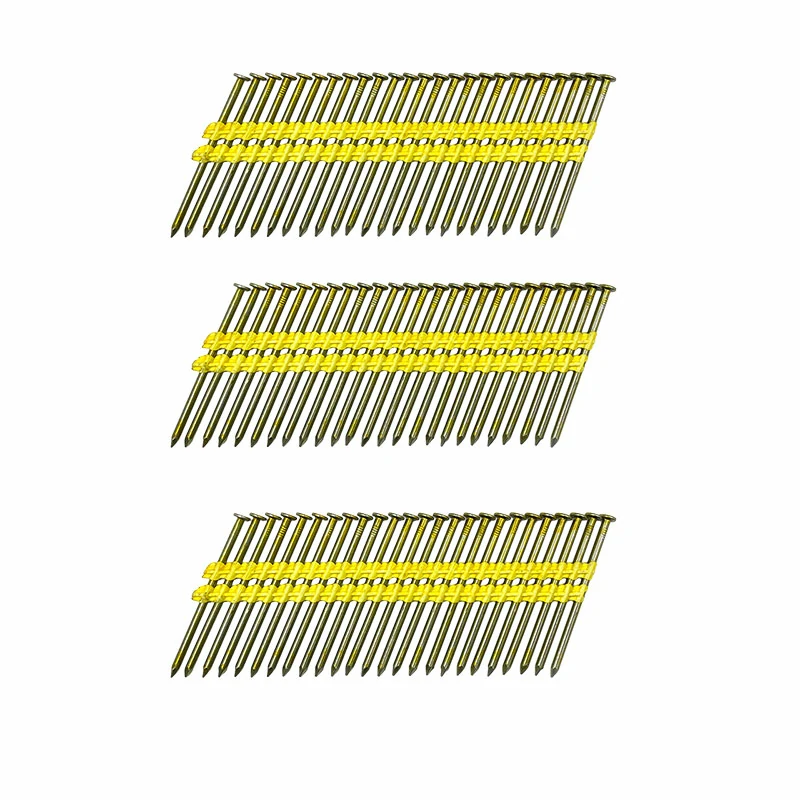

The use of 90mm framing nails can contribute to overall sustainability in several ways:

- Material Efficiency:

- 90mm framing nails are typically designed for use in larger and more substantial framing applications. Using appropriately sized nails reduces the number of fasteners needed, optimizing material efficiency and minimizing waste.

- Reduced Resource Consumption:

- Selecting the right length of framing nails for the application helps avoid over-specification. Using longer nails than necessary may require more material, leading to increased resource consumption. Choosing the appropriate nail size helps optimize resource use.

- Energy Efficiency in Manufacturing:

- Manufacturing shorter nails generally requires less material and energy compared to producing longer nails. Using 90mm framing nails in applications where longer nails are not required contributes to the energy efficiency of the manufacturing process.

- Minimized Environmental Impact:

- Shorter nails often result in smaller holes and less material displacement during installation. This can minimize the environmental impact on the surrounding materials and reduce the need for additional treatments or repairs.

- End-of-Life Considerations:

- When construction projects reach the end of their life cycle, the disposal or recycling of materials, including fasteners, becomes a consideration. Smaller, more manageable 90mm framing nails may be easier to handle during deconstruction and may have less environmental impact during disposal.

- Appropriate Use in Design:

- Choosing the right nail size aligns with sustainable design principles. By ensuring that the fasteners are appropriate for the load and application, designers contribute to the long-term durability and stability of structures.

- Avoiding Over-Engineering:

- Using excessively long nails when shorter ones would suffice can be considered over-engineering. By avoiding over-specification and selecting the appropriate nail length, construction projects can achieve sustainability goals without compromising structural integrity.

- Corrosion Resistance for Longevity:

- 90mm framing nails, when made from corrosion-resistant materials or with appropriate coatings, contribute to the longevity and durability of the structure. This can reduce the need for premature replacements and maintenance, 90mm framing nails positively impacting the project’s economic and environmental sustainability.

- Sustainable Material Choices:

- Consideration of the material composition of the framing nails is essential. Opting for nails made from recycled or sustainably sourced materials further enhances the overall sustainability of the construction project.

- Green Building Certifications:

- Some green building certification programs, such as LEED (Leadership in Energy and Environmental Design), encourage sustainable construction practices. Choosing appropriate nail sizes and materials can contribute to meeting the criteria for these certifications.

It’s crucial to note that the sustainability of construction projects involves a holistic approach, considering various elements from design and construction to maintenance and end-of-life considerations. The choice of framing nails is just one aspect of a larger strategy for achieving sustainable construction practices.

What role do 90mm framing nails play in reducing construction time and labor costs?

The use of 90mm framing nails can contribute to reducing construction time and labor costs through several factors:

- Efficient Fastening:

- Longer framing nails, such as 90mm nails, are suitable for securing larger and thicker pieces of lumber or engineered wood. This allows for more efficient fastening of structural components, reducing the number of nails required to achieve the same level of stability compared to shorter nails.

- Increased Holding Power:

- Longer nails generally provide increased holding power, allowing for a stronger connection between framing members. This can lead to a reduction in the number of fasteners needed per joint, saving time on installation and minimizing the overall labor required.

- Fewer Nail Changes:

- Longer nails can penetrate through thicker materials, reducing the need for frequent nail changes during the framing process. This efficiency can lead to time savings, as workers spend less time reloading nail guns.

- Faster Installation Speed:

- The use of longer nails allows for faster installation speeds, as workers can secure framing members more quickly with fewer fasteners. This efficiency is particularly valuable in large-scale framing projects where time is a critical factor.

- Minimized Pre-Drilling:

- In some cases, longer framing nails may reduce the need for pre-drilling holes in certain types of lumber. This can save time during the installation process, as workers can drive the nails directly into the material.

- Adaptability to Thicker Materials:

- 90mm framing nails are well-suited for attaching thicker materials, such as engineered wood products or laminated beams. The ability to efficiently fasten these materials contributes to the adaptability of the construction process.

- Reduced Handling of Shorter Nails:

- Longer nails mean less frequent handling and reloading of shorter nails in nail guns. This reduction in handling time can contribute to labor efficiency and a smoother workflow on the construction site.

- Enhanced Structural Stability:

- The increased length of 90mm framing nails allows for deeper penetration into framing members, enhancing the structural stability of the connections. This can result in a more robust and reliable construction, reducing the likelihood of rework or adjustments.

- Decreased Overhead Costs:

- Faster construction times and reduced labor requirements can translate to lower overhead costs for the construction project. This is particularly relevant in projects where labor expenses constitute a significant portion of the overall budget.

- Consistent and Reliable Fastening:

- Longer nails, when used appropriately, contribute to consistent and reliable fastening. This can result in a more predictable construction process with fewer disruptions, contributing to overall time and cost savings.

While the benefits of using 90mm framing nails are evident in terms of efficiency and labor cost reduction, it’s crucial to ensure that the selected nail length is appropriate for the specific application and complies with building codes and engineering requirements. Additionally, proper training and adherence to safety practices are essential when using power tools, including nail guns, on construction sites.